2.0 SERVICES

Our TWO major in-house services are,

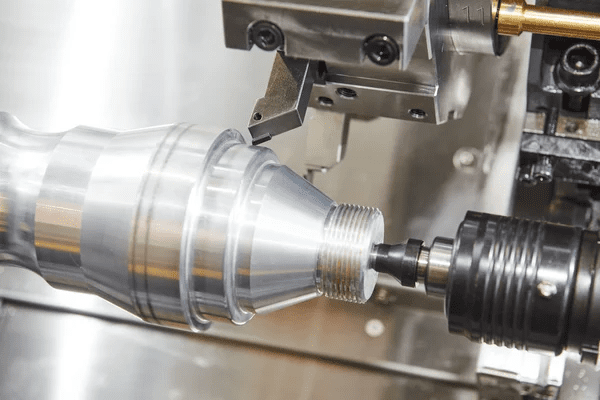

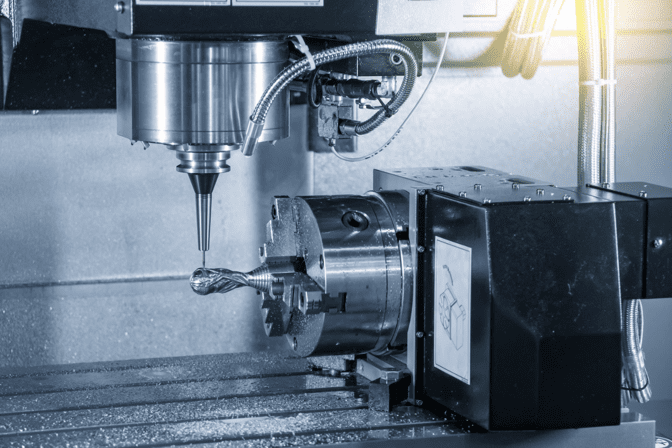

2.1 Precision Machining

2.2 Surface Finishing

2.1 High Precision CNC Turned & Milled Component Manufacturing Service:-

CNC Machined components are common in manufacturing industries. We didn’t do anything different or new. But where, the areas you can find differences are (i) Repeatability in dimensions & aesthetics (ii) Cost effective by simplicity of process (iii) Very minimal delivery failure/commitments (iv) Hassle-free communications by clear business contracts (v) Using most advance technological process methods by continual upgradation. Some of our present machining key points follows: -

2.1.1 Prototype & new developments.

2.1.2 Supply with material as well as job work.

2.1.3 Final Inspection (Parts ready to your assembling)

2.1.4 CAM Programming – Parts those need multi axis machining.

2.1.5 Additional engineering activities like; Laser marking, Heli coil insertion, special surface texture care etc,.

2.1.6 Materials handling in machining; (i) Wrought Aluminium alloy grads like 1100,5052,6061,6063,6351,6082 & 7075 (Both imported & Indian made alloys). (ii) Stainless steel – SS303, SS304 & SS316, (iii) Copper, (iv) Brass, (v) Delrin and (vi) Teflon (PTFE).

2.1.7 Reports - (i) Material properties test reports Mechanical/Chemical, (iii) Ultrasonic Test, (iv) Liquid Penetration Test), (v) Dimensional Inspection reports, and (vi) Certificate of Compliance.

2.2 Surface Finish Services:-

Anodization process in Aluminium material established (some part of the world) during 1920’s to improve physical properties and protect its surfaces from various atmospheric destruction by artificial and natural. Over 100years of technology, still it is challenging to obtain expected level of Quality/process. But here at RGPL TECH in India, you can find satisfied level of process, Because the method of process arrangements we follow similarly as Think laboratory Japan, not the technology. (Technology is very old as stated above). Our present surface finish services as follows: -

2.2.1 Anodization – Type II (Class-1 & Class2) Sulphuric acid anodizing (MIL-A-8625-TYPE-II) on Aluminium machined parts.

2.2.2 Hard Anodization – Type III (Class-1 & Class2) Sulphuric acid anodizing (MIL-A-8625-TYPE-III) on Aluminium machined parts.

2.2.3 Chemical conversion coating - Type I & II (MIL-DTL-5541) on Aluminium machined parts. (Yellow chromate & Clear chromate).

2.2.4 Passivation – Type I & Type II (MIL-STD-753), ASTM A967-96 on Stainless steel machined parts.